About Us

A Father and His Son...

Billingsley Engineering, was established in 2000 by Henry Billingsley and his son Eric Billingsley. Henry, an Aircraft Maintenance Engineer, and Eric, a Mechanical Engineer and Master Plumber banded together to start an adventure of a lifetime - a quality based business that not only knew how to install these systems, but the mecahnics of how they operate as well! Even though Henry is no longer with us, the 3rd generation will be coming into action soon!

Our Services...

At Billingsley Engineering, we have the resources to furnish you with all your plumbing and excavating needs. We provide a complete line of plumbing services from soil testing, designing and installing septic systems, to inspecting and maintenance of existing septic systems. We also can supply all your excavating and grading needs.

An All in One Contractor...

If you are looking for an all-in-one septic and excavator contractor, give us a call!

Our Services

Septic Systems

Septic System Maintenance

Septic Systems

There are a variety of different types of standard septic systems available. If you are interested in alternative types of systems, such as sand filter systems and pretreatment tanks, please give us a call for more information.

Septic System Maintenance

Septic System Maintenance

Septic System Maintenance

Proper maintenance of a septic system is essential in determining the life span of a system. If you don't want to complete this yourself, give us a call. We will ensure that maintenance is performed and recorded for your personal records.

Excavating

Community Service

Septic System Maintenance

Whether you are in need of excavation for new construction, or building a pond, give us a call and we will get on it right away.

Grading

Community Service

Community Service

If you need help moving that giant pile of dirt or need to grade for a new barn, give us a call!

Community Service

Community Service

Community Service

We believe in giving back to the community!

Soil Testing

A Soil Test is the first step for installing a new or replacement Septic System or formally known as a Private Onsite Wastewater Treatment System (POWTS). The results of the soil test determine what type of system will be required for each specific site. The days of boring a hole and utilizing water to rate a soil's hydraulic conductivity are behind us.

Now soil tests are performed by digging a hole with a backhoe and analyzing each soil layer by its physical characteristics. Examples of these characteristics are the soil type, structure, consistency, moisture content, and particle size. Once these have been determined, a hydraulic rating is assigned to each layer.

The location within the property is evaluated for limiting factors. A limiting factor is a layer of soil that consists of either periodic high ground water or bedrock. For a septic system, three feet of separation is required between the elevation in which effluent water is discharged in the absorption cell and the limiting factor below. If either high ground water or bedrock is found close to the surface, the required three feet of separation may not be feasible and proper treatment of the effluent water will not be obtained before it enters back into the water table.

Once a soil test has been completed, the septic system plans can be designed. Upon completion of the plans they are submitted to the State and/or County for review before a sanitary permit can be issued. A sanitary permit must be obtained prior to the start of installing a new system. For a conventional system, each County's Planning and Development Department approves the plans. For a mound or holding tank, the plans must also be approved by the Wisconsin State Department of Commerce. For new construction and remodeling, a sanitary permit must be obtained before a building permit can be issued.

Soil Testing

Layout of borings for a Septic Evaluation

Septic Systems

Conventional System

A Conventional Septic System is the least expensive and least complex absorption type of system that can be installed. The entire system is below the ground with the exception of the septic tank riser. This riser is placed above the surface to allow for easy access to the filter.

Mound System

This type of septic system became known as a mound due to the fact that the entire absorption field is above the ground which forms a mound of dirt in a yard.

Holding Tanks

How a Holding Tank Functions

The function of a holding tank is to serve as a temporary reservoir for effluent to a waste water treatment plant. Unlike other types of systems, an absorption field is not utilized. Collected effluent is pumped from the tank by a Licensed Waste Hauler into their truck and hauled off. A three-bedroom home, usually requires a tank five feet in diameter by eighteen feet long. This tank has a volume of 3000 gallons and is constructed of carbon steel. The size and volume of the tank depends on the number of bedrooms in the house. An alarm float is installed in the tank and is connected to a visual and audible alarm inside the house. The alarm is to let the homeowner know that the tankneeds to be pumped as soon as possible.

A holding tank is one of the most restricted types of systems that can be installed in Wisconsin. The following criteria must be met:

- The soil and site cannot be suitable for any other Wisconsin Department of Commerce approved Private Onsite Wastewater Treatment System (POWTS). (ie. A mound or similar system must be ruled unsuitable)

- The property must have holding tank "rights". This can be checked by contacting your local County Planning and Development Department.

- A holding tank pumping agreement form needs to be signed indicating that as the homeowner, responsibility will be taken to have the tank pumped as required (generally every three to four weeks).

Holding tanks are generally installed in sites that are too small for a different type of system, or the water table in the area is too high to allow for proper treatment of the effluent (wastewater). Due to the high level of maintenance and frequency of pumping for a holding tank system, this type of system, in the long run, is more work and costs the homeowner more money than standard POWTS systems.

In July of 2000, the Wisconsin Department of Commerce issued a Code requiring that if a holding tank is installed, a water meter must be installed inside the house, on the incoming water line along with an outside reader. This meter must be installed by a contractor with a Master Plumber License, such as Billingsley Engineering.

Components of a Holding Tank

Holding Tank Installation

Conventional System

What is a Conventional System

A Conventional Septic System is the least expensive and least complex absorption type of system that can be installed. The entire system is below the ground with the exception of the septic tank riser. This riser is placed above the surface to allow for easy access to the filter.

Two types of conventional systems can be installed. The first is the standard system that consists of a gravel cell and distribution laterals. The other type of system (shown above) utilizes diffusion chambers, which create a void in the soil that allows for water to collect until it percolates through the soil down to the water table.

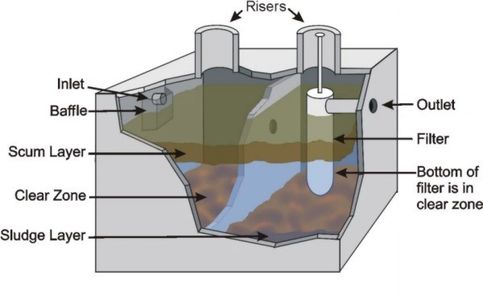

A Conventional Septic System utilizes only one septic tank and an absorption field. The tank shown above is a double-compartment tank. A septic tank for a three-bedroom house is approximately six feet wide, eight feet long, by five feet tall. The size and volume of the tank depends on the number of bedrooms in the house. It is constructed using pre-cast concrete and is watertight. All the joints on the risers are sealed with a tar based epoxy which forms and sticks to the risers when installed creating a watertight seal. The center wall inside the septic tank creates a barrier to help keep the solids in the first half of the tank.

As effluent water is retained in the septic tank, solids settle to the bottom of the tank and fats float to the top creating a soft layer of crust. As this is occurs, natural bacteria biodegrade the majority of the solids leaving a partially treated zone of water in the middle of the tank. Should solids pass to the second half of the tank, a filter is installed on the outlet that will stop any solids as small as 1/8th to 1/32nd of an inch from exiting the tank.

As water flows into the tank from the house, partially treated effluent then flows through the filter and into the absorption field. The combination of the double compartment tank and the filter greatly decreases the chance of solids making it to the absorption field. The filter must be cleaned periodically to keep it from becoming plugged.

The absorption field for this type of system consists of a couple rows of diffusion chamber placed on top of the sand. These chambers create a void in the ground that allows for water to collect until it percolates through the sand below. As the effluent percolates through the sand it is naturally filtered leaving all of the bacteria and harmful substances behind before reentering the ground water.

At Billingsley Engineering we install the diffusion type system because we believe it allows for a greater absorption area. This will increase the life span of the system.

Components of a Double Compartment Septic Tank

Absorption Field Installation

Mound System

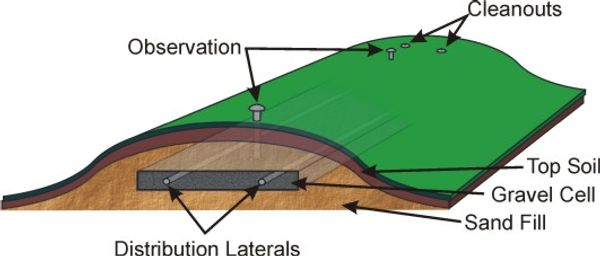

This type of septic system became known as a mound because the entire absorption field is above the ground and forms a mound of dirt in a yard. As you can see from the graphic to the right, the mound consists of nothing more than sand, washed stone, and top soil. Characteristics of a mound, such as length, width, and height, are determined by the soil test performed on the site. The length and width of the mound are determined by the hydraulic rating of the soil. The height of a mound varies based on the depth of the sites limiting factor for the soil. A limiting factor is the elevation in which either a high ground water table exists or bedrock is found. Tolearn more about limiting factors please see the Soil Test page of this web site. The approximate size of a mound for a three bedroom house is 25' wide, 90' long, and 4' tall.

Now that you know what determines the physical characteristics of a mound; lets go over the functionality of the system. As the effluent (wastewater) leaves the house, it first passes through two tanks. The first of these tanks is the septic tank. The septic tank (shown above) is know as a double compartment tank and is pre-cast, watertight concrete. For a three-bedroom home, it is typically six feet wide, eight feet long, and five feet tall, with 1000 gallons in capacity. The size and volume will change depending on the number of bedrooms in the house.

The primary purpose of the septic tank is to act as a temporary reservoir that allows time for the solids to settle to the bottom creating a sludge layer and fats to float to the top creating a soft layer of crust. As the effluent is retained in the tank, natural bacteria biodegrade the majority of the solids leaving a partially clarified liquid. Inside the septic tank is a baffle (wall) that retains the majority of the solids and fats in the first compartment. In the second compartment there is a filter. With the combination of a double compartment tank and a filter, the probability of keeping solids from flowing down to the pump tank is greatly increased. The filter must be cleaned periodically to keep it from becoming plugged.

After the effluent has been partially treated and filtered in the septic tank, it flows down to the second tank, the pump tank. The pump tank, like the septic tank, is constructed of pre-cast concrete and is watertight. However, it does not have two compartments. It typically is six feet wide, seven feet long, five feet tall, with a volume of at least 770 gallons. It may be larger depending on individual site restrictions.

Inside the pump tank is an effluent pump operated by two separate floats. The first float controls the pump on and off settings. The second float is an alarm float, which is connected to the alarm box that is mounted inside the house. This alarm will sound, audible and visual, if there is any malfunction with the effluent pump

A water resistant junction box is mounted on the pump tank riser. THis is where the electrical connections for the pump and alarm are made inside a junction box. All risers that are above the ground surface have warning labels and are locked with a cable and padlock. It is important to ensure that the risers are locked at all times to avoid accidental entry that could result in injury or death.

The absorption cell, commonly known as the "mound", is where the effluent treatment is finalized before it reenters the underground water table. The mound consists of a layer of sand on the bottom, a cell of washed stone placed in the middle, and then covered with a layer of topsoil that will support vegetation. Typically, two laterals (PVC pipe) 1 ½" in diameter are placed in the gravel cell with 3/16" holes drilled in the bottom. When the effluent pump in the pump tank turns on, the water is pumped into the laterals and is dispersed evenly through the holes in the laterals and into the gravel. As the water percolates through the stone and sand, it is naturally filtered leaving all of the bacterial and harmful substances behind before entering the water table.

Components to a mound

Absorption Cell

Septic System Maintenance

Importance of Maintenance

Importance of Maintenance

Importance of Maintenance

Proper maintenance of a septic system is essential in determining the life span of a system. It is in the hands of the homeowner to ensure that maintenance is performed and recorded for future reference.

Maintenance of a septic system begins inside the house. The following is a list a helpful hints:

- Water should be conserved whenever possible.

- Leaking faucets should be repaired. A faucet that only drips can still amount to enough water to cause a problem.

- Tasks that consume a lot of water should be done in moderation. For example, it is better to do one load of laundry every other day than to do four loads on Saturday.

- Water softeners should not discharge into the septic system.

- Harsh chemicals such as cleaning detergents should not be discharged into the system

- Fats & grease should not be discharged into nay drain. Even if they are heated up before hand, the will solidify in the transfer pipes or in the tank. When they solidify, a crust layer will form creating a dam that will restrict flow.

There are also procedures that can be done outside to help increase the systems life span.

- Clean the septic tank filter every six months or earlier if needed.

- Have the Septic tank pumped every one to two years. It is important to have all tanks and compartments pumped. Generally there are three places for a mound that need pumped, two for a conventional, and one for a holding tank. Please feel free to call if you are uncertain how many your system has.

- Avoid heavy traffic above and around the tanks and absorption field

- Divert water away from the septic tanks and absorption field. This will be done at installation but help with diverting gutters and such away from the system.

A significant investment has been put into the system. A small amount of maintenance will go a long way and will save money in the long run. Nothing is worse then when a system fails and either backs up into the house or bubbles up in the yard.

Warning

Importance of Maintenance

Importance of Maintenance

Owning a private septic system is like owning a car, if periodic maintenance is not completed; the car will not perform to expectations and may prematurely fail. The same holds true for a septic system.

To increase the life expectancy and prevent malfunctions of the Mound or Conventional Septic System, the following guidelines should be followed:

- Due to the nature of the functionality of a septic system, extensive traffic should be avoided around and above the absorption cell and tanks. If the soil on the downslope edge of a mound is compacted due to heavy traffic, the transfer of water through the soil horizontally can decrease which may lead to a prematurely failed system. Heavy traffic over the tanks may cause them to cave in.

- Extensive use of oil, high sudsing laundry detergents, chemicals, or any other anti-bacteria substances should not be discharged into the system. The use of anti-bacterial hand soaps is not considered to be excessive use and will not damage the system.

- Any inorganic materials (diapers, cigarette butts, plastics, etc.) should not be placed in the system. These materials are not biodegradable and the bacterial in the system will not be able to consume them.

- Excessive use of water will prevent the system from performing to its fullest capabilities. The daily use of water should be kept within the maximum design flow (150 gallons/bedroom).

- In order to avoid surges in the amount of water used, laundry and other large volume water uses should be averaged out. For example, one load of wash could be done each night for three days instead of three loads of wash in one night. This is one way that will help balance the bacterial level in the septic tank.

- The pump tank of a mound is equipped with an alarm, visual & audible, to indicate if the system has malfunctioned. If this occurs, immediate action should be taken to contact the installer. If a problem has occurred with the effluent pump, damage to the distribution cell can occur if proper precautions are not taken when powering the system back up.

The above guidelines also apply for a holding tank with the exception of number 5 & 6. If harsh chemicals of inorganic material are placed into the tank, the treatment facility in which the effluent is hauled to will be adversely affected.

Excavating

Basement Excavation

Grading

Foundation Backfilling

Our Sponsorships

Schools

Community Events

Community Events

We believe in giving to our community. We have supported several community schools within Kenosha County since 2002.

Community Events

Community Events

Community Events

Billingsley Engineering enjoys sponsoring several community events.

Youth Sports

Community Events

Youth Sports

We are a family owned business so family is important to us. We enjoy a variety of sports and want to promote sports in our community!

Frequently Asked Questions

Should I have a single or a double compartment Septic tank?

The life span of a system is directly related to the amount of solids that enter the absorption cell. Having a double department tank greatly decreases the amount of solids that enters the absorption field.

Can my water softener discharge into the septic system?

The salt from the softener discharge can affect the bacteria level in the tank. If the bacteria level is decreased, fewer solids will be dissolved and the chance of more solids entering the absorption field will increase. For this reason it is best to avoid discharging the softener into the system.

What kind of condition will my yard be in when the construction of a new system is complete?

When the installation is complete, all disturbed areas are graded smooth, blended in with the existing contours, prepped, and seeded. Pulverized dirt is used when covering mounds and areas above the system are covered with mulch. Depending on the time of year in which the area is seeded, new grass can be expected within a week or two.

How long will my septic system last?

The age of a system is determined by the condition in which it is operated. If a system is maintained and operated properly, a life span of twenty years can be expected. For helpful hints please refer to the maintenance and operation portion of this web site.

What can be flushed into the system?

Only organic and non-biodegradable items should be flushed into the system. As the saying goes, "If it won't rot, don't flush it down the pot."

How often should the Septic pumped?

The Wisconsin state code requires that a septic tank must be pumped every three years. It is a good idea to have them pumped every one to two years to ensure that solids do not enter the absorption field. Be sure to have all tanks and compartments of the tanks pumped.

How often should the filter be cleaned?

It is recommended by the manufacturer to clean the filter every time the tanks are serviced, or as required. If the system is heavily used the filter requires more frequent service. If the filter is not maintained properly, it may become clogged and result in a backup.

Other than the three standard septic systems, is there any other type of systems that can be installed?

Currently there are nine different Department of Commerce approved system that can be installed. If you would like additional information or have any questions on the systems that this web site does and does not cover, please give us a call.

When building a new house, what needs to be done to obtain the required permits?

The first step is to complete soil test and have the septic system plans approved. Once they are approved, a sanitary permit can be obtained and then a Building permit can be issued.

If you have any additional question lease feel free to contact us at any time.

Contact Us

We love our customers, so feel free to give us a call or send an email!

or submit an inquiry above